The Symbiotic Relationship: Internet of Things (IoT) and Industry 4.0

Industry 4.0, also known as the fourth industrial revolution, represents a paradigm shift in manufacturing and industrial processes. It leverages digital technologies to create intelligent, interconnected, and automated systems. Central to this revolution is the Internet of Things (IoT), a network of physical objects embedded with sensors, software, and other technologies that enable these objects to collect and exchange data. This essay will explore the intricate relationship between IoT and Industry 4.0, examining how IoT technologies are driving the key aspects of this transformative era.

The Core Components of Industry 4.0

Industry 4.0 encompasses several key technologies and concepts, all working in concert to achieve increased efficiency, productivity, and flexibility. These include:

- Cyber-Physical Systems (CPS): The integration of computation, networking, and physical processes, creating systems that can monitor, control, and optimize real-world operations.

- Big Data Analytics: The collection, analysis, and interpretation of massive datasets generated by industrial processes, providing insights for improved decision-making.

- Cloud Computing: The utilization of remote servers and data storage to enhance scalability, accessibility, and data management capabilities.

- Artificial Intelligence (AI) and Machine Learning (ML): The application of AI and ML algorithms to automate tasks, optimize processes, and improve predictive capabilities.

- Additive Manufacturing (3D Printing): The use of 3D printing technologies to create customized parts and prototypes, accelerating product development cycles.

- Augmented Reality (AR) and Virtual Reality (VR): Utilizing AR/VR for improved training, remote collaboration, and real-time visualization of complex processes.

The Role of IoT in Industry 4.0

The Internet of Things serves as the foundational layer of Industry 4.0, providing the necessary connectivity and data acquisition capabilities. It enables the seamless integration of various components within the industrial ecosystem, creating a dynamic and interconnected environment. The following points highlight IoT’s crucial contributions:

- Real-time Data Acquisition: IoT devices embedded in machinery and equipment collect real-time data on performance, efficiency, and operational status. This data is crucial for monitoring, diagnostics, and predictive maintenance.

- Enhanced Connectivity and Communication: IoT facilitates seamless communication between machines, sensors, and control systems, enabling automated processes and improved coordination.

- Improved Automation and Control: Through data analysis and integration, IoT empowers automation systems to make real-time adjustments, optimize processes, and enhance productivity.

- Predictive Maintenance: By analyzing real-time data and historical trends, IoT-enabled predictive maintenance systems can identify potential failures before they occur, minimizing downtime and reducing maintenance costs.

- Supply Chain Optimization: IoT sensors and trackers throughout the supply chain provide real-time visibility into the movement of goods, enhancing inventory management and logistics.

- Improved Quality Control: IoT-enabled quality control systems monitor production processes and identify defects in real time, enabling immediate corrective actions and minimizing waste.

- Enhanced Safety and Security: IoT sensors can detect hazardous conditions and trigger appropriate safety measures, contributing to a safer working environment.

- Remote Monitoring and Management: IoT enables remote monitoring of equipment and processes, allowing for proactive intervention and efficient management of assets.

Specific IoT Applications in Industry 4.0

The application of IoT in Industry 4.0 is extensive and constantly evolving. Here are a few key examples:

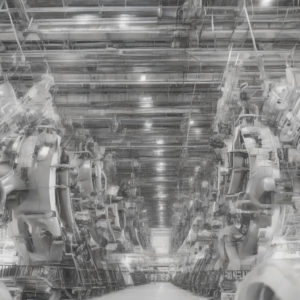

- Smart Factories: IoT-enabled smart factories utilize interconnected sensors, machines, and systems to optimize production processes, improve efficiency, and reduce costs. This includes automated material handling, real-time process monitoring, and predictive maintenance.

- Smart Agriculture: IoT sensors monitor soil conditions, weather patterns, and crop health, enabling precision agriculture techniques that optimize resource utilization and improve crop yields. This includes automated irrigation, fertilizer application, and pest control.

- Smart Energy Management: IoT sensors and smart meters monitor energy consumption in real-time, enabling efficient energy management and reducing operational costs. This includes optimizing energy production, distribution, and consumption.

- Smart Transportation and Logistics: IoT trackers monitor the location and condition of goods during transportation, optimizing delivery routes and improving supply chain efficiency. This includes real-time tracking, predictive maintenance for vehicles, and improved route optimization.

- Smart Healthcare: In healthcare, IoT enables remote patient monitoring, improving patient outcomes and reducing healthcare costs. This includes wearable sensors, remote diagnostic tools, and connected medical devices.

Challenges and Considerations

While the potential benefits of IoT in Industry 4.0 are significant, there are also several challenges and considerations:

- Data Security and Privacy: The vast amounts of data generated by IoT devices raise concerns about security breaches and data privacy. Robust security measures are crucial to protect sensitive information.

- Interoperability and Standardization: The lack of interoperability between different IoT devices and systems can hinder the seamless integration of various components within the industrial ecosystem. Industry standards and protocols are essential for interoperability.

- Scalability and Complexity: Implementing and managing large-scale IoT deployments can be complex and challenging. Effective strategies for scaling and managing IoT systems are necessary.

- Cost of Implementation: The initial cost of implementing IoT technologies can be substantial, requiring significant investment in hardware, software, and infrastructure.

- Skills Gap: The successful implementation of IoT in Industry 4.0 requires specialized skills in areas such as data analytics, cybersecurity, and IoT system integration. Addressing the skills gap is crucial for ensuring successful adoption.

- Integration with Legacy Systems: Integrating IoT technologies with existing legacy systems can be challenging, requiring careful planning and execution.

The Future of IoT and Industry 4.0

The future of IoT in Industry 4.0 is bright, with ongoing advancements and innovations driving further progress. Key trends include:

- Artificial Intelligence (AI) and Machine Learning (ML): The integration of AI and ML will enhance the capabilities of IoT systems, enabling more sophisticated data analysis, automation, and predictive capabilities.

- Edge Computing: Processing data closer to the source (the edge of the network) will reduce latency and improve real-time responsiveness.

- Blockchain Technology: Blockchain can enhance the security and transparency of data transactions in IoT systems.

- 5G and Beyond: The next generation of wireless communication technologies will provide the necessary bandwidth and speed for supporting large-scale IoT deployments.

- Digital Twins: Digital twins, virtual representations of physical assets, will enable more accurate simulations and predictive modeling.

In conclusion, the Internet of Things is inextricably linked to the success of Industry 4.0. By providing the foundational layer of connectivity and data acquisition, IoT empowers the intelligent automation, optimization, and transformation of industrial processes. While challenges remain, the ongoing advancements in IoT technologies and the growing adoption of Industry 4.0 principles promise a future of increased efficiency, productivity, and innovation across various sectors.