Revolutionizing Industry: A Comprehensive Guide to Industrial Automation Solutions

Industrial automation is no longer a futuristic concept; it’s the driving force behind increased efficiency, productivity, and competitiveness in modern manufacturing and beyond. This comprehensive guide explores a wide range of solutions currently transforming industries, addressing the challenges and opportunities presented by this technological revolution.

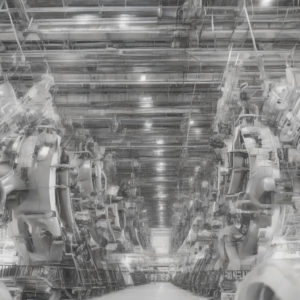

I. Robotic Automation: The Backbone of Modern Industry

Robots are arguably the most visible symbol of industrial automation. Their capabilities extend far beyond simple repetitive tasks, encompassing sophisticated functionalities that significantly impact various sectors.

- Collaborative Robots (Cobots): Designed for safe interaction with human workers, cobots enhance productivity by handling repetitive, strenuous, or hazardous tasks alongside human operators, fostering a collaborative work environment.

- Industrial Robots: These heavy-duty robots are deployed in high-volume manufacturing settings, performing tasks such as welding, painting, assembly, and material handling with speed and precision exceeding human capabilities.

- Mobile Robots (AGVs and AMRs): Autonomous guided vehicles (AGVs) and autonomous mobile robots (AMRs) revolutionize material handling and logistics within factories and warehouses, optimizing transportation efficiency and reducing manual labor.

- Robotic Process Automation (RPA): While not physical robots, RPA uses software robots to automate repetitive digital tasks, streamlining processes in areas such as data entry, invoice processing, and customer service.

II. SCADA and Industrial Control Systems: The Nervous System of Automation

Supervisory Control and Data Acquisition (SCADA) systems and other industrial control systems form the central nervous system of automated operations, enabling real-time monitoring, control, and optimization of processes across diverse industries.

- SCADA Systems: These systems monitor and control industrial processes remotely, providing crucial data for decision-making and enabling timely interventions to prevent failures or optimize performance.

- Programmable Logic Controllers (PLCs): PLCs are essential components of automation systems, automating complex processes through programmable logic and controlling various industrial equipment.

- Human-Machine Interfaces (HMIs): HMIs provide operators with a user-friendly interface to interact with automation systems, monitoring processes, analyzing data, and making necessary adjustments.

- Industrial Internet of Things (IIoT): The IIoT connects industrial equipment and systems through sensors and networks, enabling real-time data collection and analysis for improved efficiency and predictive maintenance.

III. Data Analytics and AI-Powered Automation: Intelligent Decision-Making

The explosion of data generated by automated systems necessitates advanced analytics capabilities to extract meaningful insights and optimize performance. Artificial intelligence (AI) is rapidly transforming industrial automation, enabling intelligent decision-making and predictive capabilities.

- Predictive Maintenance: AI-powered analytics predict potential equipment failures, enabling proactive maintenance interventions to prevent costly downtime and disruptions.

- Process Optimization: Machine learning algorithms analyze vast amounts of operational data to identify inefficiencies and optimize processes for enhanced productivity and resource utilization.

- Quality Control: AI-powered vision systems and other sensors enhance quality control by automatically detecting defects and inconsistencies in real-time.

- Supply Chain Optimization: AI algorithms analyze supply chain data to optimize inventory management, logistics, and delivery schedules, improving efficiency and reducing costs.

IV. Specific Industry Applications: Tailored Solutions for Diverse Needs

Industrial automation solutions are not one-size-fits-all; they must be tailored to the specific needs and challenges of individual industries. Several sectors have seen significant transformations through automation.

- Manufacturing: Automation has revolutionized manufacturing processes, increasing efficiency, improving product quality, and reducing costs across various sectors, including automotive, electronics, and food processing.

- Logistics and Warehousing: Automated guided vehicles (AGVs), automated storage and retrieval systems (AS/RS), and robotic picking and packing systems have drastically improved efficiency and reduced labor costs in logistics and warehousing operations.

- Energy and Utilities: Automation enhances safety, reliability, and efficiency in power generation, transmission, and distribution, improving grid management and reducing operational costs.

- Agriculture: Precision agriculture utilizes automation technologies such as drones, autonomous tractors, and robotic harvesters to optimize crop yields, reduce resource consumption, and improve efficiency.

- Healthcare: Automation is improving healthcare through robotic surgery, automated medication dispensing, and improved patient monitoring systems.

V. Challenges and Considerations in Implementing Industrial Automation

While the benefits of industrial automation are substantial, implementing these solutions involves challenges that require careful consideration.

- High Initial Investment Costs: Implementing automation systems requires significant upfront investments in hardware, software, and integration services.

- Integration Complexity: Integrating new automation systems with existing infrastructure can be complex and time-consuming, requiring specialized expertise.

- Cybersecurity Risks: Automated systems are vulnerable to cyberattacks, requiring robust cybersecurity measures to protect sensitive data and prevent disruptions.

- Workforce Reskilling and Retraining: Automation may displace some jobs, necessitating workforce reskilling and retraining initiatives to adapt to the changing job market.

- Data Management and Analysis: Effectively managing and analyzing the vast amounts of data generated by automated systems requires robust data management infrastructure and analytical capabilities.

VI. The Future of Industrial Automation: Emerging Trends and Technologies

The field of industrial automation is constantly evolving, with new technologies and trends shaping the future of manufacturing and other industries.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are becoming increasingly central to industrial automation, enhancing decision-making, optimizing processes, and enabling predictive capabilities.

- Digital Twins: Digital twins are virtual representations of physical assets, enabling simulation and optimization of processes before implementation, reducing risk and improving efficiency.

- Edge Computing: Processing data closer to the source (the “edge”) reduces latency and improves real-time responsiveness in automation systems.

- Blockchain Technology: Blockchain can enhance security and transparency in supply chains and other industrial processes.

- Human-Robot Collaboration: The focus is shifting towards seamless collaboration between humans and robots, leveraging the strengths of both to maximize productivity and efficiency.

VII. Conclusion (Omitted as per instructions)