Revolutionizing Industrial Spaces: A Deep Dive into Huge Industrial Ceiling Fans

Huge industrial ceiling fans represent a significant advancement in industrial climate control and energy efficiency. These powerful fans, often exceeding 24 feet in diameter, are designed to address the unique challenges presented by large, high-ceilinged industrial environments. This comprehensive guide will delve into the various aspects of these impressive machines, exploring their functionality, benefits, applications, and considerations for installation and maintenance.

Understanding the Mechanics of Huge Industrial Ceiling Fans

Unlike typical residential ceiling fans, industrial-grade models are built to withstand demanding conditions and deliver substantial airflow. Their robust construction incorporates high-strength materials capable of withstanding vibrations and consistent operation. Key mechanical components include:

- High-efficiency motors: These motors are designed for prolonged operation at high torque, ensuring consistent airflow even under heavy load. They often incorporate advanced technologies to minimize energy consumption.

- Durable blades: Large, aerodynamically designed blades are crucial for maximizing airflow. Materials such as reinforced fiberglass or aluminum are commonly used to ensure longevity and resistance to damage.

- Robust mounting systems: Industrial fans require heavy-duty mounting systems capable of supporting the substantial weight of the fan and withstanding vibrations. These systems are engineered to ensure stability and prevent damage to the ceiling structure.

- Advanced control systems: Modern industrial fans often incorporate sophisticated control systems allowing for variable speed adjustments, programmable timers, and remote operation. This allows for optimized airflow management based on environmental conditions and operational needs.

The Advantages of Utilizing Huge Industrial Ceiling Fans

The benefits of integrating huge industrial ceiling fans into industrial spaces extend beyond simple air circulation. They offer a multifaceted approach to improving operational efficiency and worker comfort:

- Significant Energy Savings: By effectively circulating air, these fans reduce reliance on HVAC systems, resulting in substantial energy cost reductions. The improved air circulation helps to stratify the air, reducing energy wasted on cooling or heating stagnant air.

- Enhanced Worker Comfort and Productivity: Improved air circulation leads to a more comfortable and productive work environment. The reduction in temperature stratification minimizes localized hot and cold spots, creating a more even and pleasant atmosphere for workers.

- Improved Air Quality: Efficient air movement helps to reduce the accumulation of dust, pollutants, and odors, leading to a cleaner and healthier work environment. This is particularly beneficial in environments with high levels of particulate matter or volatile organic compounds.

- Reduced HVAC Strain: By assisting in air circulation, these fans alleviate the burden on traditional HVAC systems, extending their lifespan and reducing maintenance requirements. This translates to both cost savings and reduced downtime.

- Improved Safety: In some industrial settings, efficient air circulation can reduce the risk of heat-related illnesses or accidents associated with poor ventilation. The improved air quality can also contribute to overall workplace safety.

Applications of Huge Industrial Ceiling Fans Across Diverse Industries

The versatility of huge industrial ceiling fans makes them applicable across a wide range of industries. Their effectiveness in large, high-ceiling spaces has led to their adoption in:

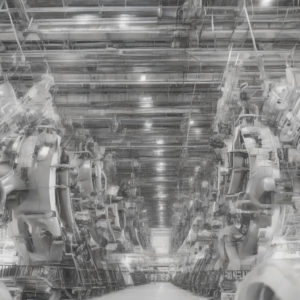

- Manufacturing Facilities: These fans are widely used in factories and warehouses to improve air circulation and worker comfort. They help to reduce the accumulation of heat and humidity generated by machinery.

- Warehouses and Distribution Centers: Maintaining a comfortable temperature in vast warehouse spaces can be challenging. These fans provide efficient air circulation, reducing energy consumption and improving worker productivity.

- Agricultural Facilities: In large greenhouses or animal shelters, these fans are invaluable for regulating temperature and humidity, ensuring optimal conditions for plant growth or animal welfare.

- Sports Arenas and Stadiums: Large indoor sports venues benefit from improved air circulation to enhance comfort for spectators and athletes.

- Retail Spaces: In large retail stores or shopping malls, these fans can create a more comfortable shopping experience while reducing energy consumption.

Factors to Consider When Choosing and Installing Huge Industrial Ceiling Fans

Selecting and installing a huge industrial ceiling fan requires careful consideration of several key factors:

- Space Dimensions: Accurate measurement of ceiling height and overall space dimensions is crucial to determine the appropriate fan size and blade length for optimal airflow.

- Airflow Requirements: The volume of air that needs to be moved will dictate the fan’s CFM (cubic feet per minute) rating. Careful assessment of the space’s needs is essential.

- Ceiling Structure: The ceiling’s structural integrity must be capable of supporting the weight of the fan. Professional assessment may be necessary to ensure safe installation.

- Motor Power and Efficiency: Choosing a motor with sufficient power and high efficiency is crucial for long-term cost savings and performance.

- Safety Features: Safety features such as blade guards, emergency stop mechanisms, and overload protection are vital for ensuring safe operation.

- Maintenance Requirements: Consider the ongoing maintenance needs of the fan, including lubrication, blade cleaning, and motor inspection.

Maintenance and Longevity of Huge Industrial Ceiling Fans

Regular maintenance is crucial for maximizing the lifespan and efficiency of huge industrial ceiling fans. A well-maintained fan will operate more efficiently, consume less energy, and require fewer repairs:

- Regular Inspections: Periodic inspections should be conducted to check for any signs of damage, wear and tear, or loose components.

- Blade Cleaning: Accumulated dust and debris on the blades can significantly reduce airflow. Regular cleaning is essential to maintain optimal performance.

- Lubrication: Proper lubrication of motor bearings is critical to ensuring smooth operation and extending the lifespan of the motor.

- Motor Checks: Regular checks of the motor’s electrical components and thermal protection devices are necessary to prevent overheating and potential failure.

- Safety Checks: Regular safety checks should be conducted to ensure that safety mechanisms are functioning correctly.

The Future of Huge Industrial Ceiling Fans

Technological advancements continue to drive improvements in the design and functionality of huge industrial ceiling fans. Future developments may include:

- Increased Efficiency: Ongoing research and development efforts focus on creating even more energy-efficient motors and blade designs.

- Smart Control Systems: Integration with smart building management systems will allow for automated control and optimization of airflow based on real-time environmental data.

- Improved Materials: The use of advanced materials will further enhance the durability and longevity of these fans.

- Reduced Noise Levels: Innovations in blade design and motor technology will contribute to quieter operation.

In conclusion, huge industrial ceiling fans represent a powerful and efficient solution for climate control and energy management in large industrial spaces. By carefully considering the factors outlined above, businesses can harness the considerable benefits of these impressive machines to create safer, more comfortable, and more productive work environments while significantly reducing energy costs.