GE Industrial Solutions: A Deep Dive into Power, Automation, and Digital Transformation

GE Industrial Solutions, a prominent player in the industrial sector, offers a comprehensive portfolio of products, services, and solutions aimed at enhancing efficiency, productivity, and sustainability across various industries. This in-depth analysis explores the company’s key offerings, technological advancements, market positioning, and future prospects.

Power Solutions: Reliable Energy for a Connected World

GE Industrial Solutions’ power solutions division is a cornerstone of its operations, focusing on reliable and efficient power generation, distribution, and management. This encompasses a broad range of technologies and services catering to diverse industrial needs.

- Power Generation: GE provides advanced gas turbines, steam turbines, and generators for various applications, from power plants to industrial facilities. These solutions are designed for high efficiency, low emissions, and optimal performance.

- Power Distribution: The company offers a comprehensive suite of power distribution equipment, including switchgear, transformers, and circuit breakers, ensuring safe and reliable power delivery across industrial settings. These products are engineered for resilience and optimized performance under diverse operating conditions.

- Power Management: GE’s power management solutions encompass advanced monitoring and control systems designed to optimize energy consumption, improve grid stability, and reduce operational costs. This includes sophisticated software and analytics platforms that provide real-time insights into power usage and system performance.

- Renewable Energy Integration: Recognizing the growing importance of renewable energy, GE Industrial Solutions offers solutions for integrating renewable sources like wind and solar power into existing grids. This helps industries reduce their carbon footprint and achieve sustainability goals.

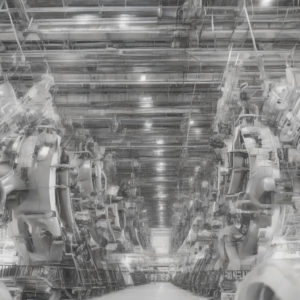

Automation Solutions: Enhancing Productivity and Efficiency

Automation plays a crucial role in modern industrial processes, and GE Industrial Solutions is a key provider of automation technologies that enhance productivity, efficiency, and safety. Their automation solutions are designed to streamline operations and optimize industrial workflows.

- Industrial Control Systems: GE offers a wide array of industrial control systems (ICS) that provide precise control and monitoring of industrial processes. These systems range from programmable logic controllers (PLCs) to distributed control systems (DCS) designed for complex industrial environments.

- Robotics and Automation Systems: GE integrates robotics and automation systems into industrial processes to enhance efficiency and reduce manual labor. These systems can be customized to suit specific industry needs, automating tasks ranging from material handling to assembly.

- Industrial Data Analytics: GE leverages data analytics to optimize automation systems. By analyzing data from various industrial sensors and equipment, GE’s analytics platforms provide real-time insights into process performance and identify areas for improvement.

- Predictive Maintenance: Using data analytics, GE’s automation solutions can predict potential equipment failures, enabling proactive maintenance and preventing costly downtime. This predictive maintenance capability ensures operational continuity and minimizes disruptions.

Digital Transformation Solutions: Empowering Industrial Operations

GE Industrial Solutions is at the forefront of the digital transformation sweeping through the industrial sector. The company offers a range of digital solutions that empower industries to leverage data-driven insights and optimize their operations.

- Industrial Internet of Things (IIoT): GE’s IIoT solutions connect industrial assets to a network, enabling real-time monitoring and data collection. This data is then used to optimize processes, improve decision-making, and enhance overall efficiency.

- Cloud-Based Platforms: GE utilizes cloud computing to store and analyze massive datasets generated by industrial operations. Cloud-based platforms provide scalability and flexibility, allowing industries to adapt to changing needs and leverage advanced analytics capabilities.

- Digital Twins: GE develops digital twins, virtual representations of physical industrial assets, allowing for simulation and optimization of operations before implementation in the real world. This reduces risks, improves designs, and enhances efficiency.

- Advanced Analytics and Machine Learning: GE leverages advanced analytics and machine learning algorithms to identify patterns, predict trends, and optimize industrial processes. These techniques enhance decision-making and provide valuable insights into operational performance.

Market Positioning and Competitive Landscape

GE Industrial Solutions competes in a dynamic and competitive market, facing challenges from established players and emerging technologies. The company’s success hinges on its ability to innovate, adapt, and meet the evolving needs of its customers.

- Technological Innovation: GE continuously invests in research and development to maintain its technological edge. This commitment to innovation is crucial for staying competitive in a rapidly evolving market.

- Strategic Partnerships: GE collaborates with other companies and organizations to expand its reach and access new technologies. Strategic partnerships play a vital role in broadening the company’s market presence and enhancing its product offerings.

- Customer Focus: GE prioritizes customer needs and satisfaction, tailoring its solutions to meet specific industry requirements. This customer-centric approach is fundamental to building long-term relationships and maintaining market share.

- Global Reach: GE’s global presence enables it to serve customers worldwide. This global reach provides access to diverse markets and opportunities for growth.

Future Prospects and Growth Opportunities

The future of GE Industrial Solutions is tied to the continued growth of the industrial sector and the adoption of advanced technologies. Several key trends will shape the company’s future prospects.

- Sustainability: The growing emphasis on sustainability presents significant opportunities for GE Industrial Solutions. The company’s solutions for renewable energy integration and energy efficiency will be increasingly important in a world striving to reduce its carbon footprint.

- Digitalization: The ongoing digital transformation of the industrial sector will drive demand for GE’s digital solutions. The company’s expertise in IIoT, cloud computing, and advanced analytics will be key to its future success.

- Industry 4.0: GE is well-positioned to capitalize on the opportunities presented by Industry 4.0, which emphasizes automation, data exchange, and intelligent manufacturing. The company’s automation and digital solutions are crucial components of the Industry 4.0 transformation.

- Emerging Markets: Developing economies present significant growth potential for GE Industrial Solutions. Expanding into these markets will be crucial for the company’s long-term growth and profitability.

Specific Industry Applications

GE Industrial Solutions serves a diverse range of industries, tailoring its solutions to meet the unique needs of each sector.

- Oil and Gas: GE provides automation, power generation, and digital solutions for optimizing oil and gas operations, enhancing efficiency, and improving safety.

- Power Generation: The company’s power generation solutions are vital for utilities and power plants, ensuring reliable and efficient electricity production.

- Manufacturing: GE’s automation and digital solutions help manufacturers improve productivity, optimize processes, and enhance quality control.

- Transportation: GE’s technologies are used in various transportation sectors, including rail and aviation, improving efficiency and safety.

- Water Treatment: GE offers solutions for water treatment plants, ensuring safe and reliable water supply.

Conclusion (Omitted as per instructions)